Product Achievements

MK III Turbine/ Cryogenic Plant.

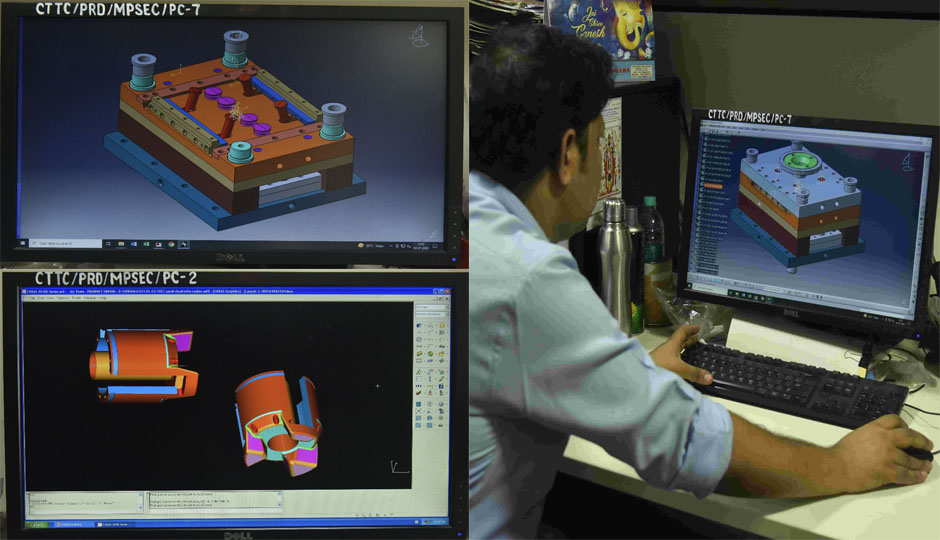

Description:

A Cryogenic Pump manufactured by the Tool Room was tested for full functionality at Linde, UK in Aldershot. The pump passed all tests and had minor glitches such as vacuum brazing. For the first time a highly complex product has been fully manufactured and passed in the first trial abroad.

Blank from the tool is used by MSME / other industry to manufacture pressure cooker.

Description:

M/S. Hindalco Industries Ltd., Belur has assigned a job for design and manufacturing of combined blanking tool for RCBL for 375mm, 465mm and 410 mm diameter aluminum circle. The nature of job is critical due to its positional and dimensional accuracy and it is also a combined tool for different blank size.

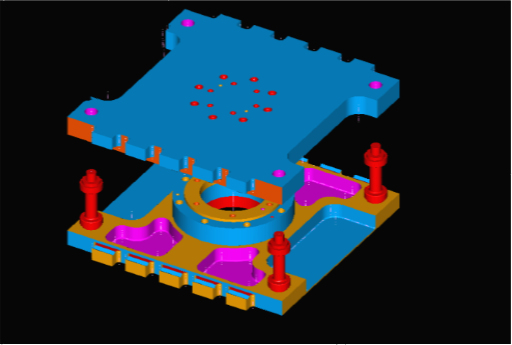

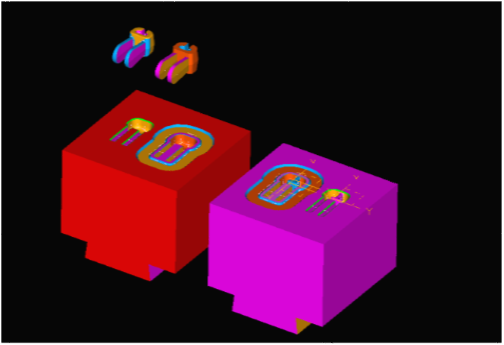

The Centre has successfully designed, manufactured and supplies Nine (9) Cavity Blanking Tool

Description:

The Centre has successfully designed, manufactured and supplies Nine (9) Cavity Blanking Tool for Rs.5/- with spares for India Govt. Mint, Hyderabad. The said Blanking Tool will be working in the Schular Press Machine (Model: SAK 125) manufactured by Germany which has a capacity at a maximum speed of 500 strokes per minute. The tool consists of various parts with various materials and some of parts required heat treatment to withstand the shearing load.There are also 9 Nos. of Tunsten Carbide and 9 Nos. of Carbide Punches in the tool. As the clearance die and punch are very close (i.e., 80 micron), the said tool required to maintain high dimensional and positional accuracy while running in high speed. Earlier this tool is used to be imported by India Govt. Mint. Tool is running successfully.

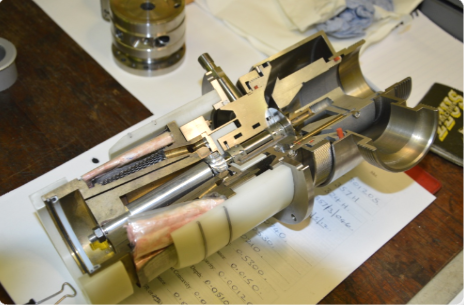

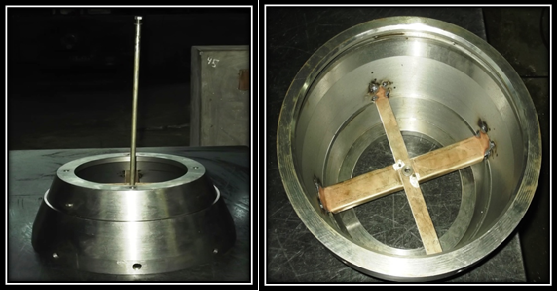

Adaptor Assembly and Spider cone (Defence).

Description:

This Centre manufactured parts of Aerial Bomb i.e., Adaptor, Spider Cone and Arming Spindle assembly with high accuracy for OFDC Dum Dum. These components were certified by Centre for Military Airworthiness Certificate (CRMILAC) and they are subsequently released for use in field.

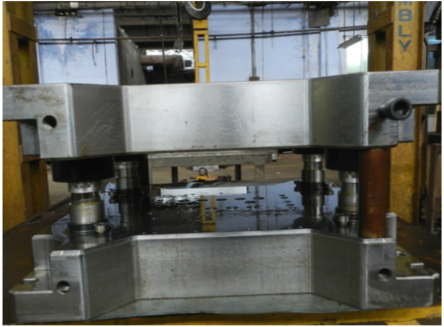

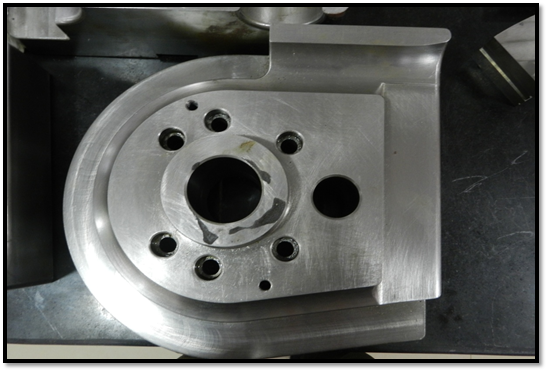

Steel Valve Body (Chemical Industry).

Description:

M/S. EMC Ltd, Kolkata has placed an order for designing and manufacturing of forging die .The die got it designed with the assistance from 2D component drawing. The component has a critical and complex structure with various blending radius. The component drawing generated with the help of 3D CAD software.

Tube Bending Dies (Power Plant).

Description:

This Centre has executed a job received from M/S. Alstom, Durgapur and machining has been done on 3D curve profile on the nozzle. The criticality of this job is pertaining to machining on 3D curve profile with high accuracy. It is a developmental job and after successful trial we will receive batch production jobs.

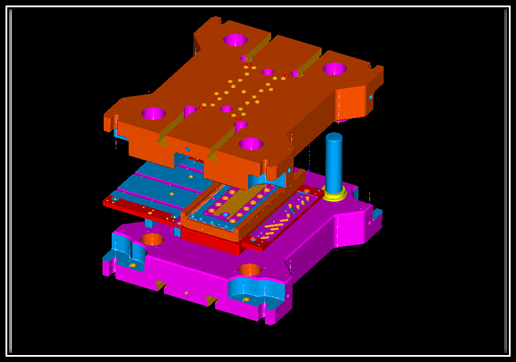

Coin Blanking Tool For Rs. 5 -.

Description:

The Centre has successfully designed, manufactured and supplies Fourteen Cavity Blanking Tool for Rs. 1/- with spares for India Govt. Mint, Kolkata. The said Blanking Tool will be working in the Schular Press Machine (Model: SAK 125) manufactured by Germany which has a capacity at a maximum speed of 500 strokes per minute. The tool consists of various parts with various materials and some of parts required heat treatment to withstand the load of the machine. There are also 14 Nos. of Tunsten Carbide and 14 Nos. of Carbide Punches in the tool. As the clearance die and punch are very close (i.e., 80 micron), the said tool required to maintain high dimensional and positional accuracy while running in high speed. The tool is working successfully.